Automatic liquid packaging machines are essential equipment for companies involved in the production and distribution of liquid products. These machines are used for packaging various types of liquid products such as water, juice, milk, oil, and other liquids. But what is the cost of automatic liquid packaging machine? The cost of an automatic liquid packaging machine varies depending on the type of machine and its specifications.

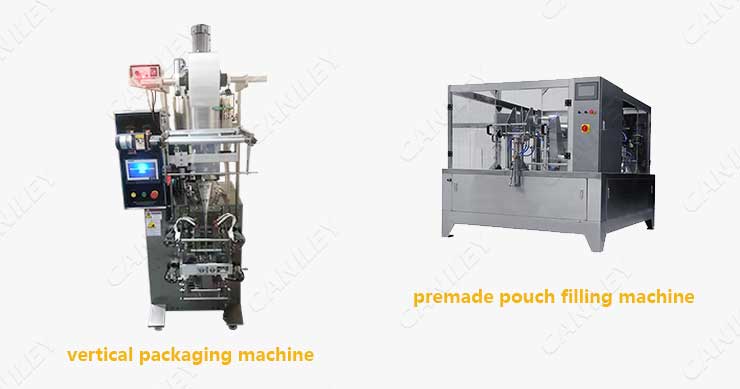

There are generally two types of automatic liquid packaging machines: vertical packaging machines and premade pouch packaging machines. Let’s discuss the cost of each type of machine in detail.

Vertical Packaging Machine:

A vertical packaging machine is a type of machine that uses a roll of packaging film to create bags or pouches. The machine forms, fills, and seals the bags or pouches in a vertical position. The cost of a vertical packaging machine for liquid products can range from $4,000 to $20,000, depending on the machine’s features and specifications. Some factors that can affect the cost of a vertical packaging machine include the following:

- Capacity: The capacity of the machine, which can affect its price. Machines with higher capacities typically cost more than those with lower capacities.

- Material: The material used to construct the machine can also affect its cost. Machines made from high-quality materials, such as stainless steel, are generally more expensive than those made from lower-quality materials.

- Features: Different types of bags will also affect the cost of the machine.

Premade Pouch Packaging Machine:

A premade pouch packaging machine is a type of machine that uses pre-made pouches to package liquid products. The machine fills the pouches with the liquid product and then seals them. The cost of a premade pouch packaging machine for liquid products can range from $20,000 to $50,000, depending on the machine’s features and specifications. Some factors that can affect the cost of a premade pouch packaging machine include the following:

- Capacity: The capacity of the machine, which is measured in pouches per minute (PPM), can affect its price. Machines with higher capacities typically cost more than those with lower capacities.

- Material: The material used to construct the machine can also affect its cost. Machines made from high-quality materials, such as stainless steel, are generally more expensive than those made from lower-quality materials.

- Features: Additional features such as automatic filling, sealing, and labeling can also increase the cost of a premade pouch packaging machine.

It is important for companies to carefully consider their needs and budget when choosing an automatic liquid packaging machine that will meet their production needs.