The application of shrink wrap machine is very wide, and the operation is relatively simple. We will send work instructions to every customer who buys our machines. But for others, they may not know how to operate the machine, so we wrote this article to explain the shrink wrap machine work instructions.

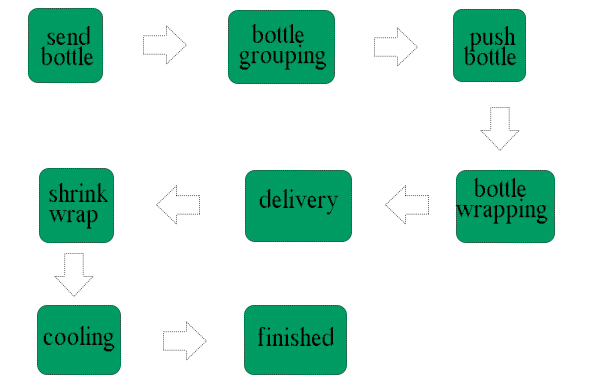

The shrink wrap machine work flow chart is as follows:

The following introduction takes packaging bottles as an example:

1. Delivery. This step mainly includes three steps, sending bottles, grouping, and testing. Grouping can adjust the spacing of the isolation plates according to the size of the bottle.

2. Press bottle. The accurate cooperation of the bottle pressing mechanism and the bottle blocking mechanism realizes the rapid and accurate grouping of the bottles. When changing bottles, only need to adjust the longitudinal position of the connecting plate on the guide rod.

3. Push the bottle. The roller chain drives the bottle push rod (stepless speed regulation) to push the bottles into the coating area in turn. When the product is wrapped with film, the proper amount of film will make the film have a good thermal shrinkage effect.

4. Wrap film. When reaching the position of the coating zone, the air cylinder pushes the film cutter component to move down along the guide rod through the linear bearing, and the upper and lower film feeding mechanism releases the film at the same time. The upper and lower films of the lower cutter seat are connected and cut at the same time to complete a wrapping.

5. Delivery. After wrapping, the product is transported to the heating tunnel.

6. Shrink wrap. This part consists of an outer box, an air duct and an inner box. The outer box body is made of carbon steel plate and thermal insulation materials to ensure full use of energy. The air duct and inner box body are all made of 304 stainless steel to ensure a clean and hygienic environment for product heat shrinkage. The working temperature can be set arbitrarily through the interface function keys (set according to the type and output of the shrink film used).

Above, the whole wrapping process is over.

Thanks so much…But I need further its Working instruction…!