In today’s fast-paced world of manufacturing and packaging, efficiency and precision are key. Automatic cartoning machines have emerged as invaluable tools in the packaging industry, streamlining the process of carton packaging for a wide range of products. From food and pharmaceuticals to cosmetics and consumer goods, these automated machines have revolutionized the way products are packaged, offering numerous benefits for both manufacturers and consumers.

What is an automatic cartoning machine?

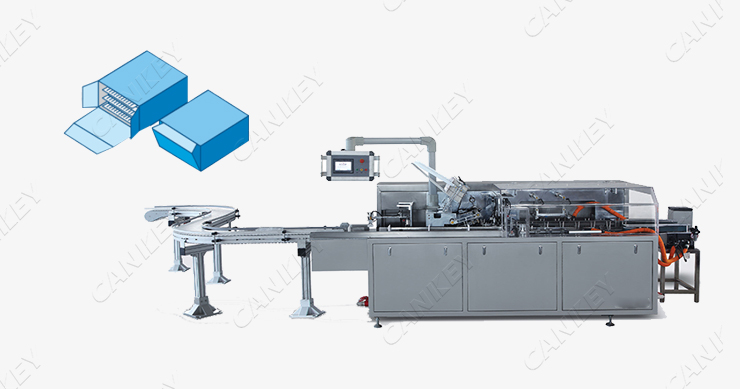

An automatic cartoning machine, also known as a cartoner, is a piece of automated equipment designed to erect, fill, and seal cartons or boxes for packaging various products. These machines are essential for efficiently packaging a wide variety of items, such as blister packs, bottles, tubes, pouches, and more. They come in different forms, including horizontal and vertical cartoners, with each type catering to specific packaging requirements.

What is the use of automatic cartoning machine?

Efficiency and speed:

One of the primary benefits of automatic cartoning machines is their ability to significantly enhance production efficiency. These machines can fill and seal cartons at a much faster rate than manual labor, allowing manufacturers to meet high production demands with ease. This not only reduces labor costs but also ensures a consistent and speedy packaging process.

Versatility:

Automatic cartoning machines are versatile and adaptable to various packaging needs. They can handle different types and sizes of cartons and a wide range of products, making them suitable for industries such as food, pharmaceuticals, cosmetics, and more. This adaptability makes them a valuable asset for manufacturers with diverse product lines.

Improved product quality:

The precise and consistent operation of automatic cartoners ensures that each product is packaged with care. This helps maintain the quality and integrity of the items being packaged, reducing the risk of damage or contamination during the packaging process. It is particularly critical in industries like pharmaceuticals where product quality and safety are paramount.

Reduced labor costs:

By automating the cartoning process, manufacturers can reduce their reliance on manual labor, resulting in cost savings. This not only lowers labor expenses but also minimizes the risk of errors and inconsistencies that can occur with human operators.

Enhanced product presentation:

Automatic cartoning machines can be equipped with various features to improve the presentation of products in cartons. These machines can include labeling, date coding, and other customization options, ensuring that products are not only safely packaged but also presented attractively to consumers.

Compliance and traceability:

In regulated industries like pharmaceuticals, automatic cartoning machines offer a reliable way to ensure compliance with industry standards and regulations. They can be equipped with systems for serialization and tracking, allowing manufacturers to trace products from production to distribution.

Automatic cartoning machines have become indispensable tools in the packaging industry, offering efficiency, versatility, and consistency in the cartoning process. Whether it’s food, pharmaceuticals, cosmetics, or consumer goods, these machines play a vital role in ensuring that products are safely and attractively packaged. With their ability to reduce labor costs, enhance product quality, and provide compliance solutions, automatic cartoners are a key component in modern manufacturing and packaging operations. As technology continues to advance, these machines will likely become even more sophisticated and essential in the packaging landscape, driving innovation and improving product packaging across industries.